|

Serial number: YD-500GL5HVE

Weldable materials: carbon steel, stainless steel

Load duration: 100%

Input voltage: 3-phase 380V

Main welding methods: CO2, MAG, MAG pulse, stainless steel MIG, stainless steel MIG pulse.

Main welding materials: carbon steel, stainless steel.

Construction method:

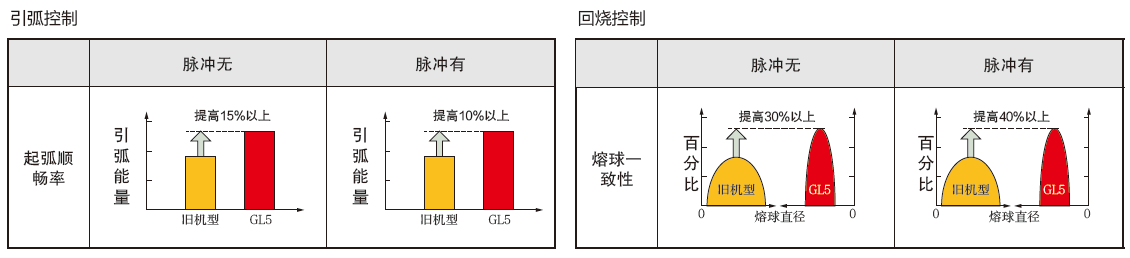

Arc ignition and burnback control IBC

Pulse fixed arc length control ALC

Root

High and low pulse HL-Pulse

Stainless steel pulse S-Pulse

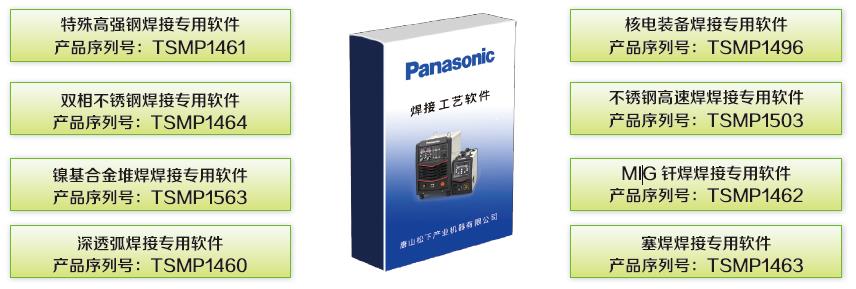

Welding process software

Welding method

Arc ignition and burnback control IBC

IBC (IniArcand BBK Control), the arc ignition and ball cutting control technology, the arc ignition adopts asynchronous curved surface acceleration control, and the ignition energy is dynamically adjusted, which can quickly establish and stabilize the molten pool and improve the success rate of arc ignition; the burn-back adopts controllable The dynamic cutting molten ball technology improves the consistency of the molten ball size; at the same time, the shortening of arc ignition and burn-back time can speed up the welding cycle and improve production efficiency.

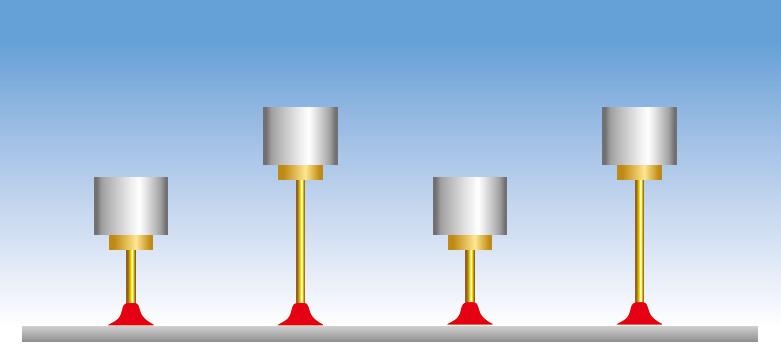

Pulse fixed arc length control ALC

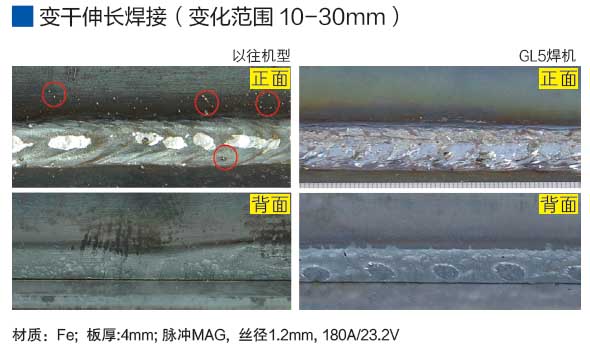

Pulse fixed arc length control ALC (Arc Length Consistence), which dynamically adjusts the pulse parameters during the welding process to ensure that the arc length remains unchanged when external disturbances (such as dry elongation changes) occur, while improving the dynamic characteristics and adaptability of the arc ; Uniform pulse frequency adjustment makes the welding sound softer, thereby greatly reducing the noise generated by welding; strictly control the transition form of pulse by drop to improve the consistency of droplet shedding, improve the quality of welds, and reduce welding defects.

Dry elongation changes, arc length unchanged

Drying and elongation welding (variation range 10-30mm)

Root

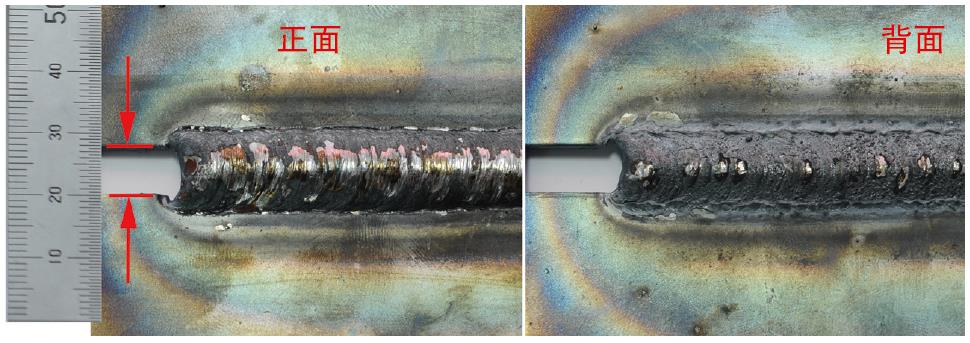

Root is a short-circuit transition method with low heat input. Through fine waveform control, the arc is more stable, the heat input is lower, and the droplet transition is more uniform, thereby improving the arc bridging ability, especially suitable for large gap welding, open groove bottom welding and vertical upward welding. During the bottom welding, the work load of root removal is greatly reduced, even without root removal, the back penetration is smooth and uniform, and the swing can be reduced or even no need to swing during vertical welding.

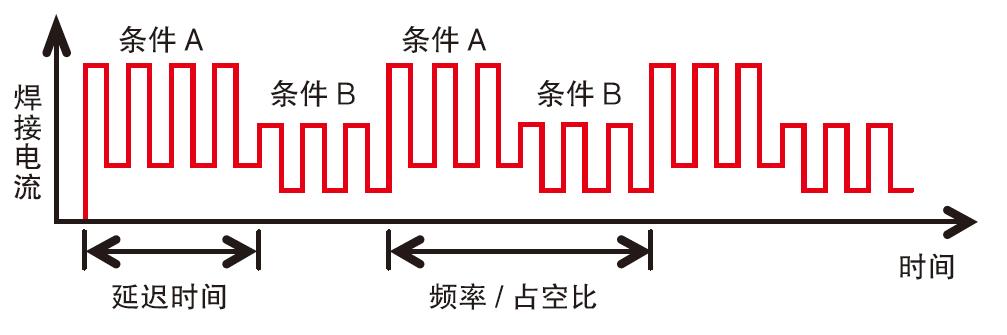

High and low pulse HL-Pulse

HL-Pulse pulse is also called double pulse. It superimposes a low-frequency pulse on top of a high-frequency pulse. The high-pulse is fast welding and the low-pulse reduces the heat input of the weld. The heat input is adjusted through the alternating stepped output of energy, and the scale-like weld can be obtained without swinging. Commonly used for welding thin plates of aluminum and stainless steel.

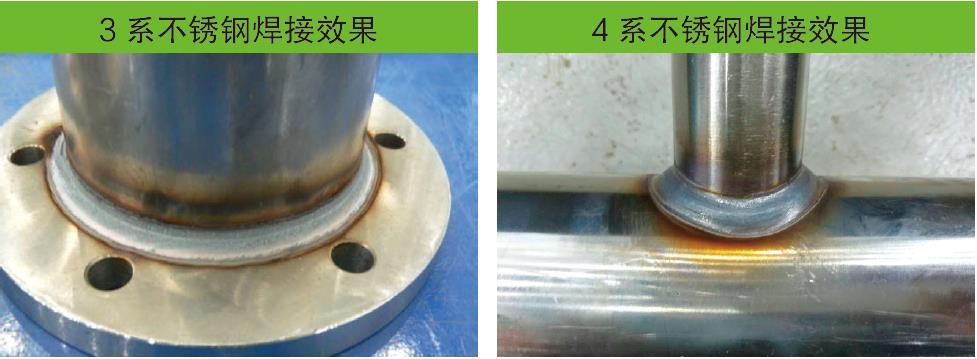

S-Pulse (SUS pulse)

S-Pulse contains a variety of stainless steel welding data. In view of the difference in welding characteristics between the three-series stainless steel and the fourth-series stainless steel materials, special welding data can be automatically retrieved, so that the welding arc can reach a stable state and obtain a smooth droplet transfer, ensuring low welding spatter and achieving a good weld seam forming.

Process software

Process software packages are expert data developed for special materials or processes, and are welding solutions based on specific welding materials, base materials, and gases. It is a standard option in addition to the standard welding machine. In addition, for the special requirements of users, customized process software can be developed for specific needs.