|

Serial number: YD-350GR5HGE

Weldable materials: carbon steel, stainless steel

Load duration: 60%

Input voltage: 3-phase 380V

Main welding methods: CO2, MAG, stainless steel MIG.

Main welding material: carbon steel.

Construction method:

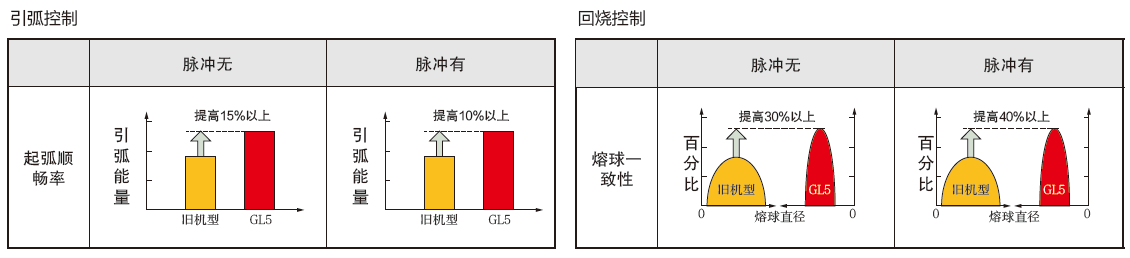

Arc ignition and burnback control IBC

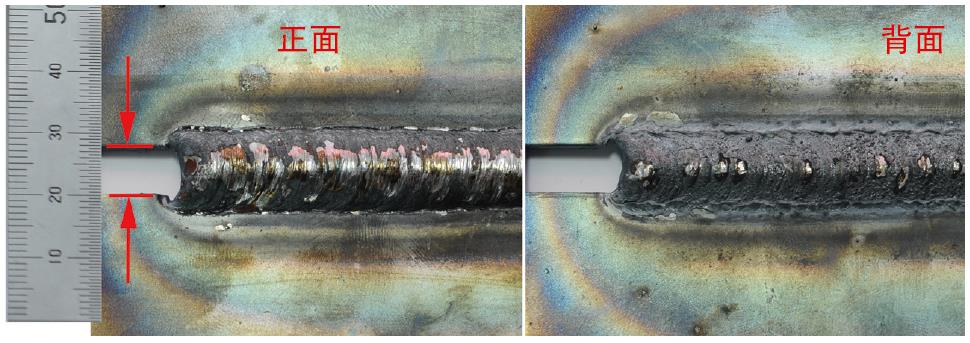

Root

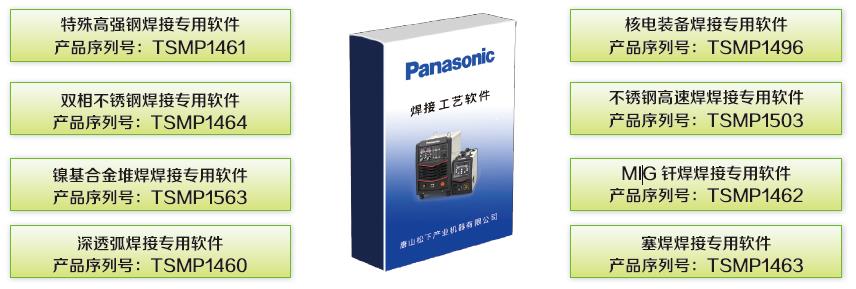

Welding process software

Welding method

Arc ignition and burnback control IBC

IBC (IniArcand BBK Control), the arc ignition and ball cutting control technology, the arc ignition adopts asynchronous curved surface acceleration control, and the ignition energy is dynamically adjusted, which can quickly establish and stabilize the molten pool and improve the success rate of arc ignition; the burn-back adopts controllable The dynamic cutting molten ball technology improves the consistency of the molten ball size; at the same time, the shortening of arc ignition and burn-back time can speed up the welding cycle and improve production efficiency.

Root

Root is a short-circuit transition method with low heat input. Through fine waveform control, the arc is more stable, the heat input is lower, and the droplet transition is more uniform, thereby improving the arc bridging ability, especially suitable for large gap welding, open groove bottom welding and vertical upward welding. During the bottom welding, the work load of root removal is greatly reduced, even without root removal, the back penetration is smooth and uniform, and the swing can be reduced or even no need to swing during vertical welding.

Process software

Process software packages are expert data developed for special materials or processes, and are welding solutions based on specific welding materials, base materials, and gases. It is a standard option in addition to the standard welding machine. In addition, for the special requirements of users, customized process software can be developed for specific needs.